WHAT YOU DON'T KNOW ABOUT SIGMATEKNIK

29 . 06 . 2022

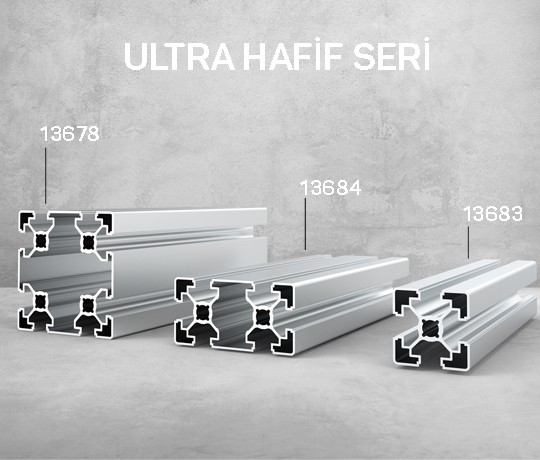

There are approximately 90 types of our conveyor, sigma and surface coating profiles. In addition to these, we can bring your designs to life by making new mold studies for the profiles you have specially designed. In addition, we have a wide range of connection accessories suitable for all our profiles. For more detailed information about connection accessories, you can review our current catalog.

Thanks to the special alloy raw material we use while producing our aluminum sigma profiles, our products are not in F22 condition, but in F25 condition. In this way, our products are compared to the standard F22 condition; It is more durable and high performance in the same geometries. Since the material is easier to machine, it maximizes productivity. It is advantageous in terms of both cost and production performance.

Our aluminum sigma profiles are available in 6020 mm lengths as standard in our stocks. Your production demands can be met up to a maximum size of 6800 mm for anodized surface and up to a maximum of 12000 mm for pressed (raw) surface. Aluminum sigma profiles have three different channel structures as 6, 8, and 10 mm. The most accurate result will be achieved in the applications to be made with the most suitable channel structure for you. The accessories to be used are also separated according to these channel structures. The standard thickness of our anodized surfaces is at the level of 10-12 microns. Depending on your place of use, in order to increase the hardness of the surface, you can increase the anodized thickness of your profiles to the desired level and produce according to your demand.

The awareness of aluminum sigma profiles in industry and production areas continues to increase day by day. It is possible to get detailed information by contacting our team who are experts in their fields and have technical equipment.

NEWS ARCHIVE